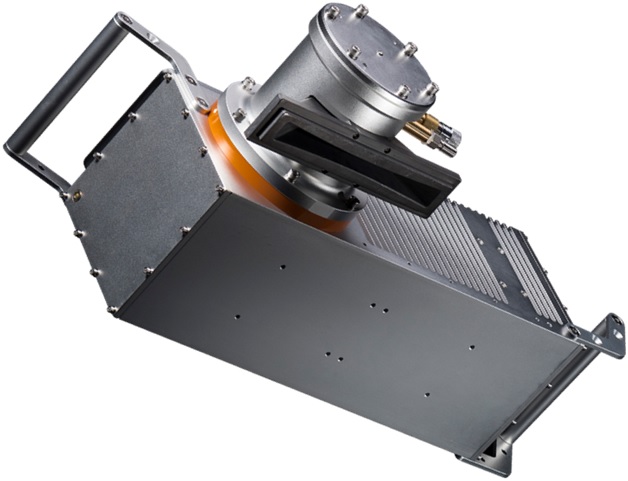

Precision imaging and inspection applications rely heavily on high-quality X-ray technology, which is critical for industries requiring extreme accuracy and reliability. From electronics manufacturing and aerospace engineering to medical research and advanced materials analysis, businesses depend on the microfocus X-ray source for precise diagnostics, quality assurance, and detailed component evaluation. Selecting the right equipment involves careful consideration of performance metrics, operational reliability, and seamless integration with existing systems to meet both current and future needs.

Partnering with experienced manufacturers ensures access to cutting-edge technology, consistent output, and long-term durability, which are essential for maintaining high standards of inspection and imaging. Equally important is collaboration with reliable power supply providers, as stable energy delivery, operational safety, and efficiency are crucial for optimal performance. By carefully evaluating both equipment and supplier expertise, organizations can enhance productivity, reduce operational risks, and achieve superior outcomes in highly specialized applications.

1. Understanding Microfocus X Ray Source Capabilities

Focal Spot Size and Resolution: Smaller focal spots produce higher resolution images, which is critical for inspecting tiny components or identifying fine defects. The choice of focal size directly influences the level of detail and accuracy in imaging results. Selecting the right spot size ensures precise diagnostics and reliable quality control across diverse applications.

Power Range and Energy Levels: Different applications demand varying energy outputs to image or analyze components effectively. Choosing the right source that supports both low- and high-voltage requirements provides flexibility for multiple tasks. Proper energy selection ensures optimal penetration and consistent performance for all inspection needs.

Material Penetration and Application Fit: These sources must be capable of penetrating the materials being tested while maintaining clear and detailed images. Evaluating the source specifications against the industry and specific use-case scenarios ensures suitability. This assessment guarantees accurate results and reduces the risk of imaging errors or incomplete inspections.

Working with experienced X-ray source manufacturers ensures that microfocus sources are optimized for precision tasks, offering consistent performance and reliable imaging results for complex inspection processes.

2. Evaluating Manufacturer Expertise and Reliability

Years of Industry Experience: Manufacturers with extensive experience bring proven reliability and deep technical expertise to the design and production of X-ray equipment. Their track record reflects advanced engineering capabilities and consistent adherence to industry standards. Partnering with experienced providers ensures confidence in both product performance and long-term operational success.

Certifications and Compliance: ISO certifications and regulatory compliance are essential indicators of quality, safety, and consistency in manufacturing. Adhering to industry standards ensures equipment meets rigorous operational and safety requirements. Choosing certified manufacturers reduces risk and guarantees reliable performance for critical inspection applications.

After-Sales Support and Maintenance: Top manufacturers provide comprehensive after-sales services, including installation, calibration, and routine maintenance. This proactive support minimizes downtime and keeps equipment performing at peak efficiency. Reliable service also extends the lifespan of X-ray systems, ensuring a strong return on investment.

Choosing the right manufacturers directly impacts efficiency and operational continuity. Reliable partners not only supply cutting-edge equipment but also provide technical expertise, troubleshooting support, and guidance on system optimization.

3. Technology Advancements and Future-Readiness

Digital Imaging and Automation: Modern sources integrate with digital detectors and automation systems, allowing faster inspections and higher throughput.

Software and Analytics Compatibility: Advanced imaging software enables detailed analysis, defect detection, and reporting, enhancing decision-making efficiency.

Scalability and Upgradability: Future-ready X-ray solutions allow easy upgrades, modular expansions, and compatibility with emerging technologies, ensuring long-term investment value.

Selecting forward-thinkingmanufacturers enables companies to stay ahead in rapidly evolving industries. Technology integration ensures superior imaging, operational efficiency, and adaptability to future inspection requirements.

4. Maintenance, Reliability, and Cost Considerations

Predictive Maintenance and Longevity: Regular monitoring and scheduled maintenance help identify potential issues before they escalate, extending the overall lifespan of the equipment. Proactive care reduces unexpected downtime and ensures consistent performance. This approach maximizes reliability and keeps inspection processes running smoothly.

Total Cost of Ownership: Evaluating total cost involves more than the initial purchase price; operating expenses, maintenance, and service support are equally important. Understanding long-term costs helps businesses make informed investment decisions. This ensures both financial efficiency and sustained operational performance.

Warranty and Service Agreements: Comprehensive warranties and accessible technical support provide security and peace of mind for equipment users. Prompt service reduces delays and protects against unexpected failures. Reliable agreements guarantee continuous operational reliability and long-term satisfaction with the investment.

Evaluating these factors with reputable manufacturers guarantees that businesses receive durable, cost-effective solutions that maintain consistent performance over the long term.

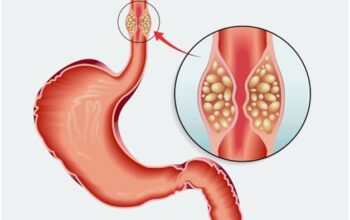

The Role of High Voltage Power Supply Manufacturers

Microfocus X-ray sources rely on a consistent high-voltage input to ensure clear, accurate imaging and prevent potential equipment damage. Stable energy delivery is essential for maintaining operational efficiency and minimizing interruptions, allowing the system to perform optimally across all inspection tasks. Modern power supply manufacturers incorporate advanced safety protocols, including overload protection, thermal management, and emergency shutdown systems, which safeguard both equipment and personnel while ensuring long-term reliability.

Additionally, power supplies must be fully compatible with specific X-ray sources to allow precise control over voltage, current, and operational parameters. Seamless integration enhances imaging accuracy and overall system efficiency, while customizable solutions provide the flexibility needed to meet unique application requirements. Partnering with high-voltage power supply manufacturers ensures that the microfocus X-ray system operates safely, efficiently, and reliably, preventing fluctuations that could compromise performance or reduce equipment lifespan.

Choosing the right microfocus X-ray source involves more than selecting equipment; it requires evaluating technical specifications, manufacturer expertise, power supply compatibility, and future-readiness. Businesses that partner with trustedmanufacturers ensure high-quality imaging, operational efficiency, and safety.

For organizations seeking expert guidance, cutting-edge technology, and reliable support for X-ray systems, VJ X-Ray provides professional solutions tailored to industry-specific requirements, helping companies achieve precision, efficiency, and growth in competitive markets. Collaborating with trusted manufacturers ensures stable energy delivery and optimal performance, complementing advanced X-ray equipment. Investing in the right equipment and strategic partnerships transforms inspection processes into a competitive advantage while securing long-term reliability, operational efficiency, and consistent imaging quality.