Modern advanced technology together with industrial implementations make effective heat management an increasingly vital necessity. The heatsink aluminum profiles rank as the top thermal management solution option. Various devices including computers and industrial machinery as well as LED lighting systems require specialist parts made from heatsink aluminum profiles to function properly. This article explains Heatsink aluminium profiles alongside their purposes while discussing why JM Aluminium became a leader in aluminum distribution.

An Understanding of Aluminum Heatsink Profiles

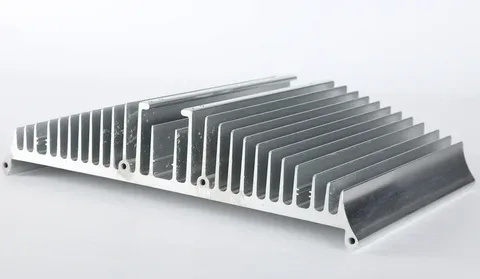

Elevated temperatures of electronic components and heat-emitting devices receive effective heat dissipation through specially engineered heatsink aluminum profiles which are aluminum extrusions. Production of these profiles happens through extrusion which pushes aluminum material into precise shapes featuring fins or other elements that boost surface area. The increased contact surface area causes the heat to be discharged from its source to its surroundings more quickly.

The primary role of heatsink aluminum profiles consists of thermal management for sensitive parts to avoid damage resulting from excessive heat. Due to its light weight combined with its superior heat conductive abilities and lower price compared to copper aluminum serves best as the material for heat dissipation applications. The profiles exhibit superior durability because aluminum provides excellent resistance against corrosive elements under harsh conditions.

Systems of Renewable Energy

Solar power installations and other renewable energy systems use power inverters with control systems that need heatsink aluminum profiles to sustain proper operating temperatures. The heat generation from solar inverters reaches high levels during operation because they convert solar panel DC power into usable AC power. Such essential parts achieve extended operating lifetime through effective cooling provided by heatsink aluminum profiles.

Vehicle Uses

The car industry applied heatsink aluminum profiles in three essential applications including engine control units, LED headlights and electric vehicle battery management systems. Modern automobile heat management requirements increase because automobiles contain rising amounts of electrical components. The automotive industry finds efficient compact and lightweight cooling solutions through heatsink aluminum profiles.

Manufacturing Equipment

Due to the demanding operating conditions faced by industrial equipment, massive amounts of heat develop. The operating temperature requires heatsink aluminum profiles which appear throughout power controllers and motor drives as well as industrial electronic applications. Industrial requirements demand dependable components thus aluminum heatsinks stand out because of their ability to withstand harsh conditions and demonstrate excellent longevity.

Advantages of Aluminum Extrusions in Modules

Modular aluminum extrusions possess flexibility and versatility as the key elements of their comprehensive benefits package. These profiles become ready using multiple attachment methodologies that simplify their combination with other components to integrate into other systems. Manufacturers use this flexible technology to create special cooling solutions without developing entirely fresh design concepts.

The maintenance and enhancement process for modular aluminium extrusions becomes straightforward because of their modular structure. No modifications made to single components or their insertion or replacement affect the overall performance of the system. These profiles serve industries that necessitate periodic maintenance since they provide adaptable solutions to different requirements that emerge over time.

How Things Are Made

A number of exacting procedures are involved in the creation of premium heatsink aluminum profiles. The first step in the procedure is choosing the right aluminum alloy, usually one with a high heat conductivity. Specified forms with fins and heat-dissipating elements are added to profiles by heating the alloys through shaped dies.

The profiles receive secondary operations after extrusion that can either enhance their functional properties or their visual aesthetics through procedures such as cutting and treatments like machining surface treatment or anodizing. During anodizing a protective oxide coating forms while also enabling flexibility for users to choose desired color options.

Businesses such as JM Aluminium have mastered these production techniques, allowing them to create heatsink aluminum profiles with accurate measurements and superior thermal characteristics. Because of their proficiency with aluminum extrusion technology, intricate profile designs that optimize cooling efficiency while preserving structural integrity may be produced.

Options for Customization

Customization for particular applications is one of the advantages of heatsink aluminum profiles. Different fin heights, thicknesses, and densities can be used to construct profiles that strike the ideal balance between heat dissipation ability and spatial limitations. Surface treatments can increase the transmission of heat or offer more defense against external influences.

JM Aluminium allows customers to specify exact requirements for their heatsink aluminum profiles through their customization service. Each custom-made profile receives optimized thermal control because customers can exactly define specifications via JM Aluminium’s personalization services.

Sustainability Elements

The environmentally friendly elements of heatsink aluminum profiles demand recognition in this modern period of ecological consciousness. The requirement of energy for aluminum recycling is less than 5% of new production costs thus making aluminum one of the most easily recycled components. Used heatsink aluminum profiles become available for new product creation when they reach the end of their life cycle so they can form an integral part of circular economic systems.

Furthermore, these profiles help to save energy overall by facilitating the more effective operation of electrical equipment and systems. Over time, less waste and resources are used because properly cooled electrical components last longer and function more effectively.

The Prospects for Aluminum Heatsink Profiles

Effective thermal management solutions will become more and more necessary as technology develops. Future advancements in heatsink aluminum profiles could involve new designs that optimize cooling efficiency while consuming the least amount of material, improved surface treatments that further increase thermal conductivity and integration with phase-change materials for even more effective heat dissipation.

The need for increasingly compact yet extremely efficient heatsink aluminum profiles will be fueled by the growing trend of electronics becoming smaller. Similarly, new opportunities for thermal management solutions using modular aluminum extrusions will arise as renewable energy systems and electric vehicles proliferate.

Conclusion:

Modern thermal management systems reliant on heatsink aluminum profiles operate in various industries. These profiled aluminum products stand essential because they excel at heat dissipation with their dual capabilities of structural support.

JM Aluminium together with other businesses leads innovative modular aluminum extrusions research because they constantly develop new profile designs and manufacturing methods to meet evolving customer needs. Heat sink aluminum profiles of superior quality will assume greater importance in future as technology advances while effective cooling requirements escalate.

The technology they rely on functions with reliable effectiveness through heatsink aluminum profiles that quietly distribute heat in solar inverters, LED lights and computer systems. Their unacknowledged influence contributes fundamentally to contemporary manufacturing as well as product design for the continuous operation of all the countless devices that power their modern world.