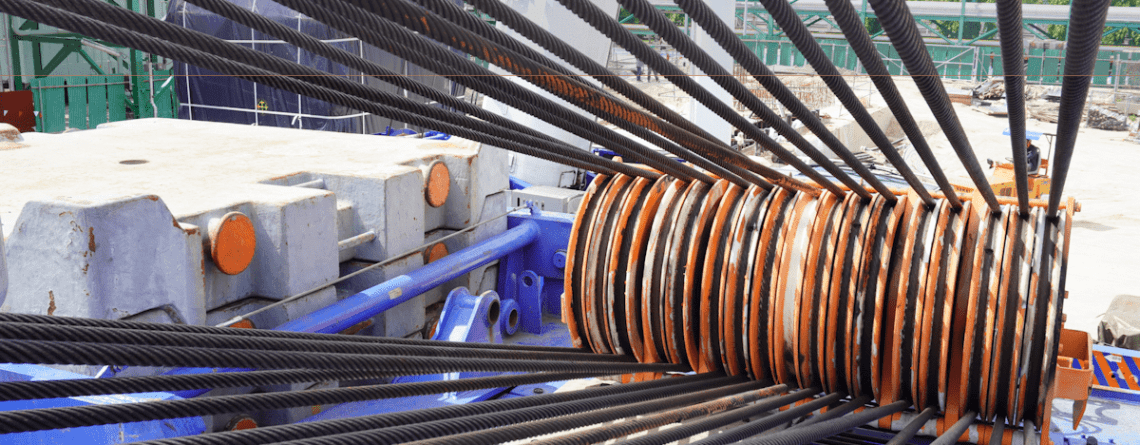

The reliable strength that can lift, hold, and transfer weights repeatedly is created by combining a few key components with several moving parts to form a crane. A Crane Wire Ropes Usha Martin is essential as it supports all loads and protects the cargo, workers, and work site. Wire ropes are sturdy instruments that withstand heavy, frequent use but are not indestructible.

Many people mistakenly believe that wire ropes are safe since they don’t need any care or maintenance, but in reality, they put in a lot of work behind the scenes. But this isn’t the case since neglecting proper maintenance—like cleaning and lubrication—can lead to rust, corrosion, and wire breakage.

How Well It Handles Heavy Lifting

Wire rope hoists can lift much heavier loads than other hoist kinds because wire ropes are constructed using several wires, which distribute the load’s weight across multiple vital metal components. In contrast to chain hoists, which can only lift to 30,000 kg, some rope hoist systems can elevate an astounding 90,000 kg. It makes them a better choice for occupations where heavy lifting is a regular occurrence.

The Safety Of Using It

Security is also another key benefit of this technology. Even if one of the wires or strands breaks, there is enough to keep the weight supported until it can be dropped since there are many of them.

Its Enhanced Resilience –

The lifting medium will last long since it is resistant to wear and tear, rust, and corrosion. You may also get this rope with a galvanized finish, which makes it much more resistant to these harmful chemicals.

Many Options Are Available –

Any time you need to raise or lower anything, you may find a rope hoist system that works for you.

Please Tell Me What Wire Rope Hoists Are

Industries, factories, and massive foundries often use wire rope hoists to elevate heavy objects. Like conventional electric hoists, which utilize steel chains to advance loads of varying weights, these electric hoists use electricity. Quite a few factories make use of this gear. Nevertheless, crane steel wire rope are the way for hefty lifting since they provide safer working loads (SWLs) than regular chain hoists. It has led to the rise of wire ropes in popularity in the manufacturing sector.

Moisten The Ropes And Wires Of The Crane To Delay Their Breakdown

Lack of lubrication and internal or external fatigue caused by bending or crushing are often the main. You may prevent both types of damage if you know the maintenance needs of your wire ropes and how to use them properly.

The easiest way to make your wire ropes last longer and stronger is to relubricate them with the right oil for their kind, usage, and weather.

Time To Clean Up Before Greasing

In addition, the new lubricant may use wire rope cleaners to eliminate any existing lubricant contamination, dirt, and salt. You may accelerate water retention and early corrosion if residue and built-up material stay inside the rope. It can also mask underlying issues along the string. To lubricate effectively, it must remove debris and substitute a high-quality lubricant.